Description

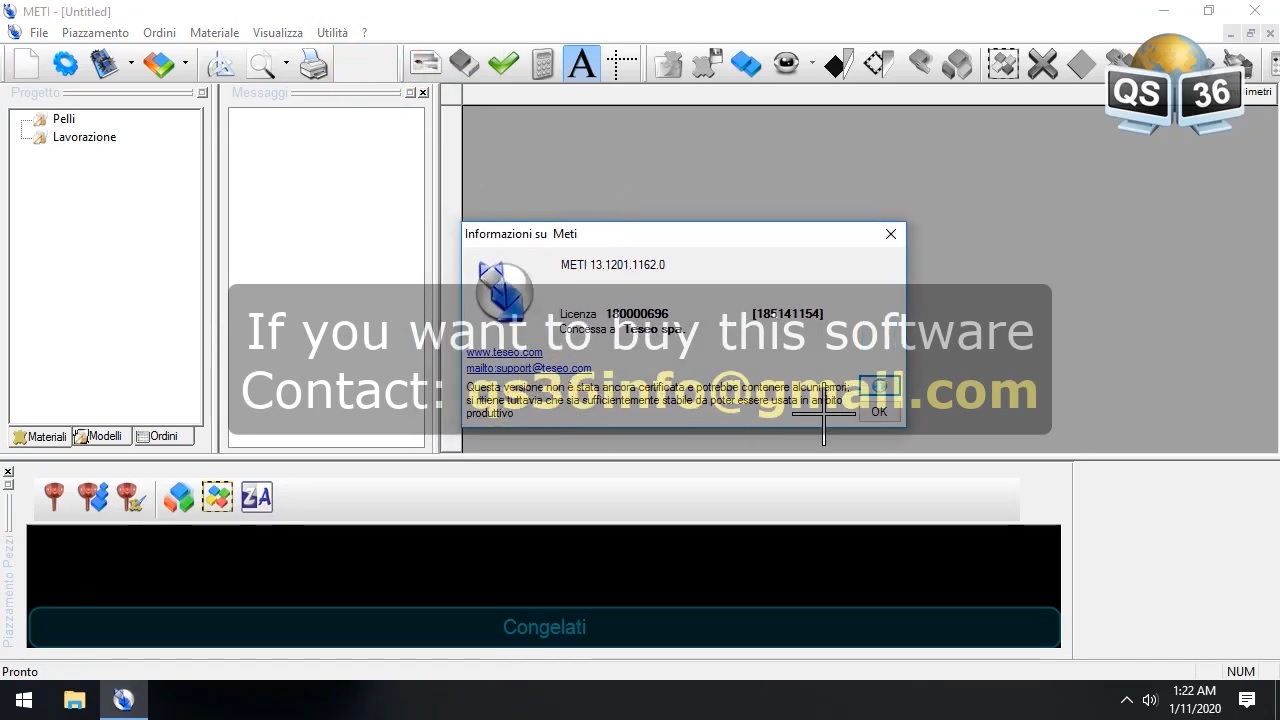

METI is not only the throbbing heart of all our systems: it is a powerful software that makes unrivaled the high performances reached by TESEO integrated solutions. It is a discreet and reliable partner who supports you throughout the management of your orders.

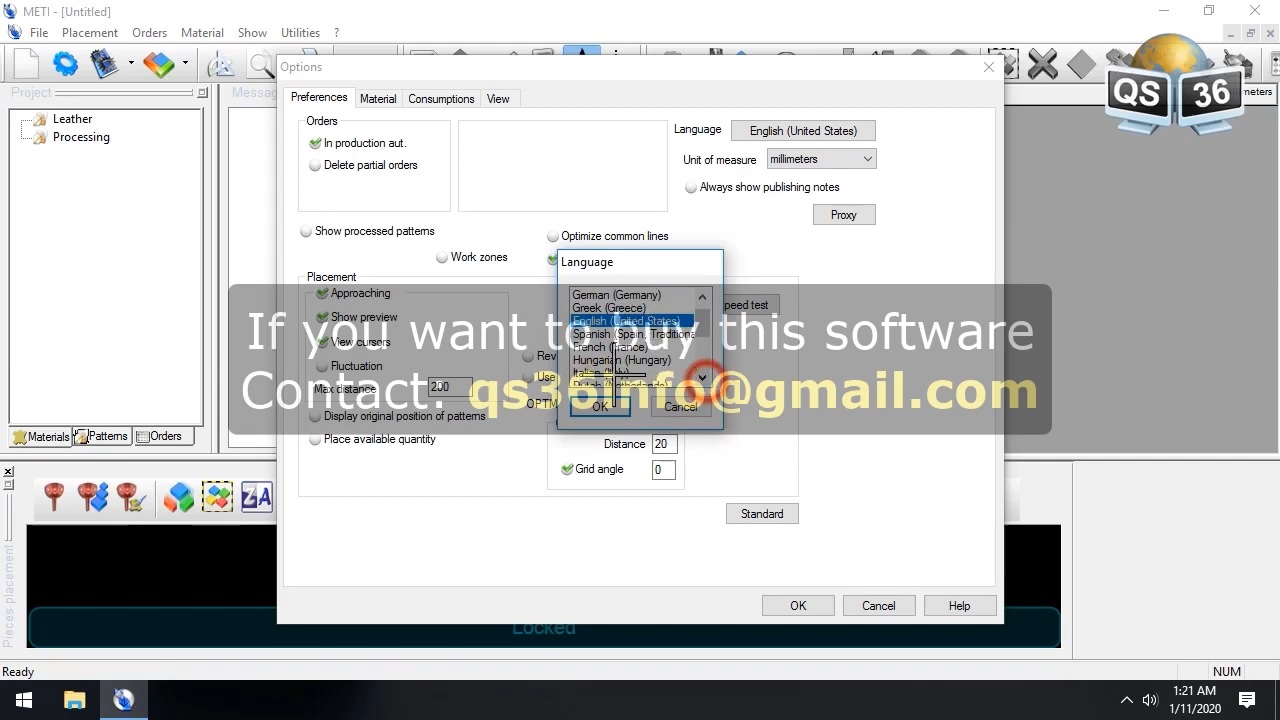

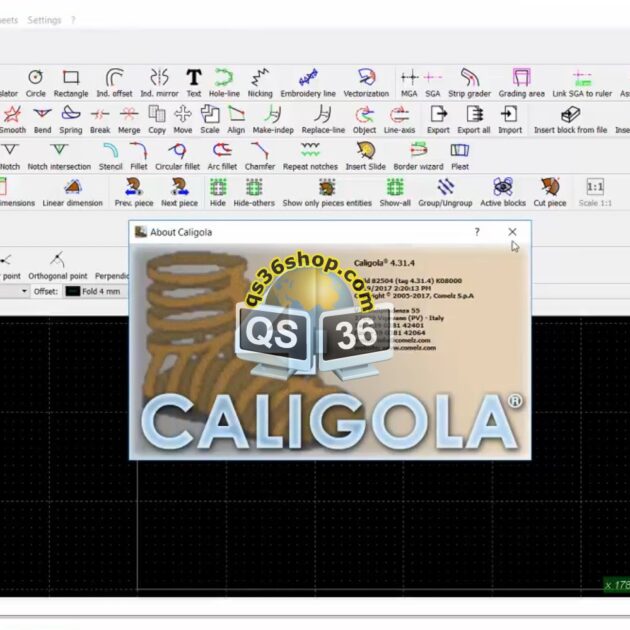

It quickly interfaces with CAD software design for the management of patterns, sizes and components.

It handles the scanning of the hide, the automatic recognition of quality areas and defects , and pilots the screening during all phases: inspection, placement, cutting and collecting. It is the fastest and most powerful nesting system in the world: in just 20 seconds it is able to save up to 15% of the leather compared to a manual placement.

To be effective and make the job easier and profitable, experience is necessary

Knowing the leather to select it according to its natural defects and to waste it as little as possible; getting a fast and precise cut without ruining the precious surface; making particular workings as micro-punches, punches and signs; recognizing patterns, logos and printed drawings to make them fit with the finished product. It is an experience that we gained supporting our customers. Observing their skills allowed us to design and implement an intelligent, sophisticated and fully integrated system between software, optical devices and cutting machines: a system that TESEO has developed in over thirty years and that continues developing unabated

Sophisticated, mathematical algorithms will place the pieces to be cut on the available leather, optimizing the exploitation of the useful surface of the leather with a saving up to 15%.

METI takes only 20 seconds to do what an experienced operator does in 6 minutes. In addition, the automatic recognition of the various quality areas and defects avoids a priori the waste of defective pieces.

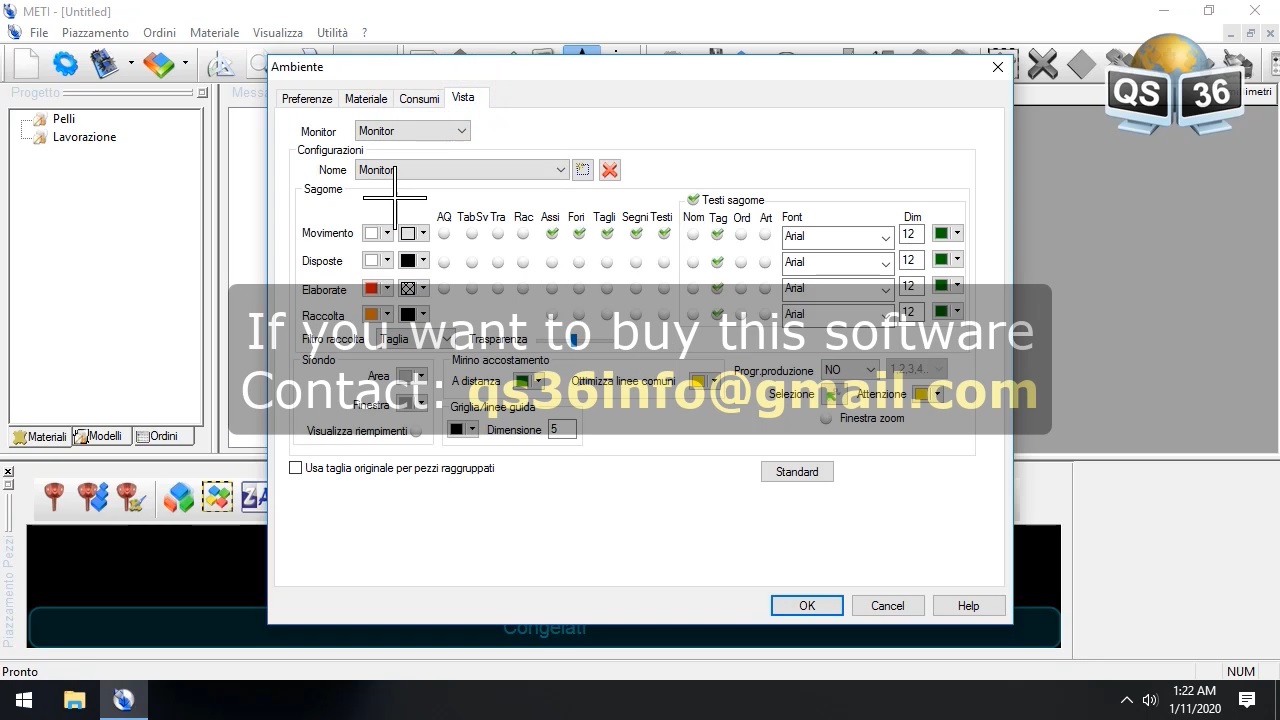

The nesting of the pieces is done according to the different quality areas assigned to each component and its details. METI optimizes nesting on the criteria used, ensuring maximum performance possible, with minimal waste. Simultaneous display on the monitor and on the leather, allows the operator total control and any possible manual intervention.

REAL-TIME REPORTS AND DETAILED STATISTICS

METI provides in real-time all the useful statistics to verify and organize the use and the performance of the TESEO cutting solutions to get the highest productions capacity. The statistics can be customized and organized in accordance to the specific necessities to enable a simple and immediate reading of all the sensitive data.

DIAGNOSIS AND REMOTE SUPPORT

METI has a real-time connection with the software NESSO for immediate diagnosis and remote support, finding a quick solution to 95% of the events. It allows to make periodical remote audits to monitor the correct use of the production equipment and to prevent possible issues or malfunctions.